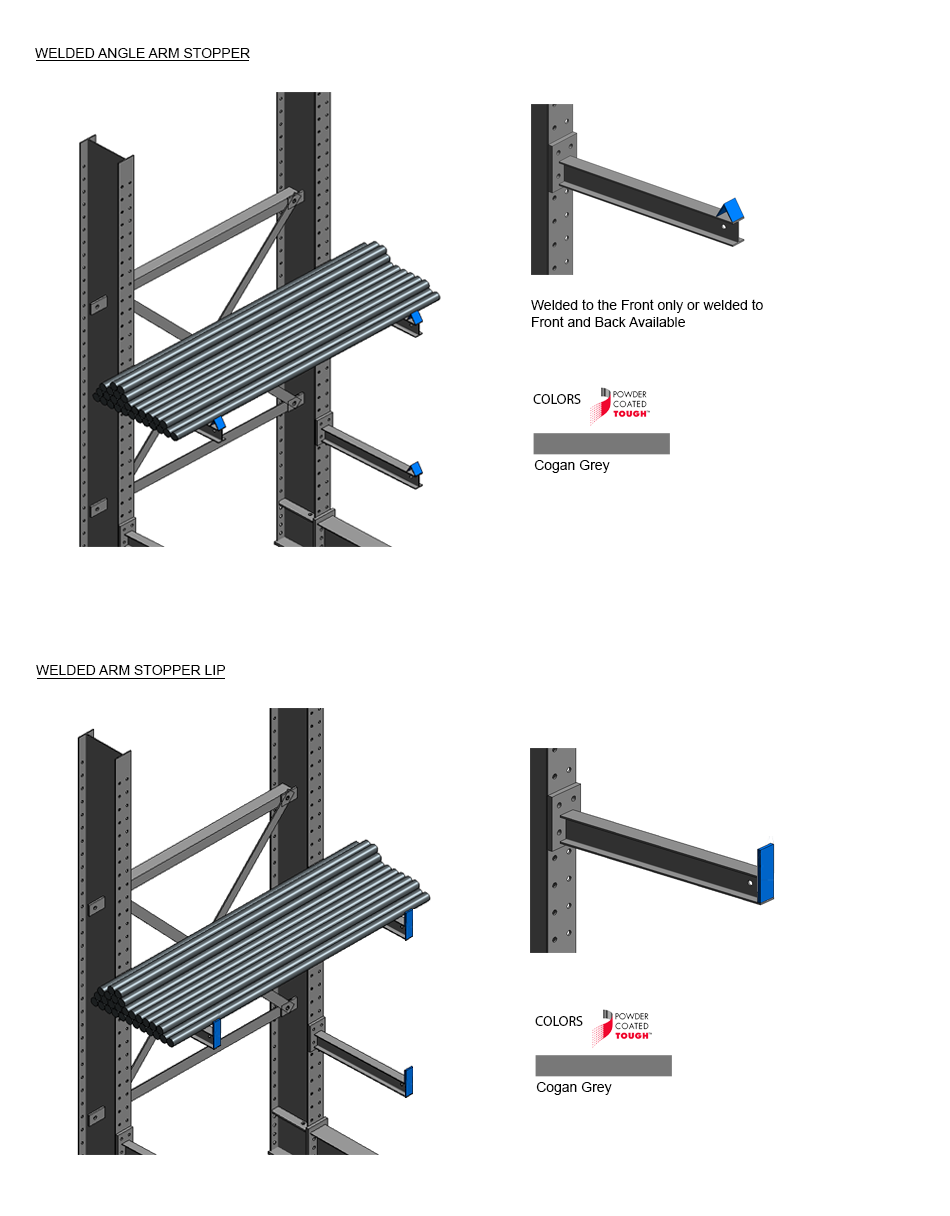

The removable and fixed stopper pins are used to help prevent the product materials from slipping or rolling off the rack arms. There are four different types of stopper pins: removable or fixed stopper pins, welded arm stopper lips and welded angle arm stoppers. Angle arm stoppers are welded on top of each arm to keep materials centered on the arms.

- Click here to download Printer Friendly Summary (PDF).

The removable and fixed stopper pins are used to help prevent the product materials from slipping or rolling off the rack arms. There are four different types of stopper pins: removable or fixed stopper pins, welded arm stopper lips and welded angle arm stoppers. Angle arm stoppers are welded on top of each arm to keep materials centered on the arms.